Committed to Speed, Quality and Value!

JDS Technologies, Inc © 2014 All rights reserved.

JDS Technologies, Inc. | 1299 Airport Road | Oneida, TN 37841 | (423) 286-6190 | (423) 286-6192 (Fax) | [email protected]

JDS Oilfield Products | 806C I-10 Frontage Road | Scott, LA 70583 | (337) 237-6856 or (337) 230-0346 | (337) 456-6173 Fax | [email protected]

Home | Markets | Products | Competencies | AboutJDS | ContactJDS | Employment | Sitemap

Molding

JDS Technologies, Inc. is an ISO 9001 certified provider of rubber and plastic molded products for a wide range of markets and industrial applications. We proudly maintain a clean, modern manufacturing facility with the latest most technologically advanced rubber and plastic molding machinery available. Our three rubber and plastic molding competencies include: Compression Molding, Transfer Molding, and Injection Molding.

JDS Technologies, Inc. has almost 10 years experience specializing in the manufacturing of high quality molded rubber and plastic products; including seals, gaskets, o-rings, hoses, and custom products in various rubber, plastic, and elastomer compounds. Our company’s reputation for distinction and quality has been built on our ability to provide our valued customers with the most effective designing, engineering, and manufacturing solutions. JDS Technologies, Inc. is committed to consistently providing custom precision molded rubber and plastic products to meet all of your blueprint and tolerance specifications.

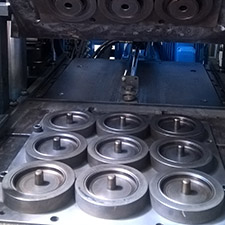

Compression Molding

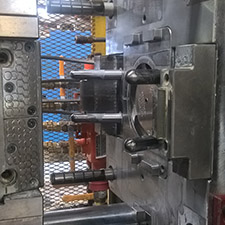

Injection Molding

Plastic Molding

Compression Molding

This method of molding involves a press, heat, and pressure to compress loaded material into a mold. The process totally fills the mold cavity and is held until cured. It’s very cost effective and widely used method in the rubber and plastic industries for low to medium volume production parts where faultless finishes and the tightest tolerances are not required.

Transfer Molding

This method of molding also uses a press, heat, and pressure of a mold, however, a plunger forces loaded material through a passage into the mold cavity until it’s cured. While typically more costly and time consuming than compression molding, transfer molding is preferred when the customer needs a complex product, tight tolerances, while still maintaining needed production volumes.

Injection Molding

This method of molding involves feeding material into a press, which is then heated and injected into the mold cavity until it’s cured. It’s considered the most cost effective and best choice for high volume production runs of small product sizes which require tight tolerances and little to no finishing.

Cryogenic Deflashing and Finishing

JDS Technologies, Inc. uses a non-abrasive finishing method called cryogenic deflashing to remove excess flash from rubber products. Flash is typically found in areas where the mold comes together, and excess molded material escapes cavity during the production process. In this method the cryogen, usually liquid nitrogen, is used to cool the rubber product until the flash becomes brittle and falls off during the tumbling process. Cryogenic deflashing is a very versatile and effect finishing method that maintaining part integrity, critical tolerances, extends mold life, and reduces price per piece on finished product.

Laser Marking System

JDS Technologies, Inc. offers customers high speed product identification via our laser marking system. Industrial material applications include various rubbers, plastics, and anodized metals. Virtually any text, bar codes, logos, and graphics can be delicately and accurately marked with this technology. This is a value-added process which allows our customers products be set apart from the competition.